Aluminum-alloy-roof-rack-platfo

Overview

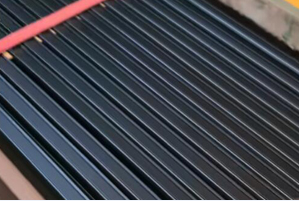

.The aluminum alloy roof rack platform is mainly made of aluminum profile as the main frame, with a small amount of PC alloy ABS material used in some parts (such: elbows and pressure plates), and all connecting screws are made of 304 stainless steel screws and nuts. The aluminum profiles are all reinforced and thickened, and thickness of the aluminum material reaches 2.6mm at the thickest part, and is combined with longitudinal aluminum plates and horizontal aluminum bars, so it has an excellent load- performance.T-slotted connection points are provided in the middle and around the edges to anchor with T-screws at any position.The surface of the profile has undergone a deep electrophoretic process and a high-quality powder spraying process, so it has excellent rust and corrosion resistance,which is enough to cope with various extreme harsh environments. This is suitable for 99% of models, such as off-road vehicles, urban SUVs, pickups, and commercial vehicles.

Material | Aluminum alloy、PC alloy and ABS |

Surface treatment process | electrophoretic process、Spray powder process |

Size(length * width) | 1.2*1.23、1.4*1.23、1.6*1.23、1.8*1.23、2.0*1.23、2.2*1.23(Unit: meter)、Other custom sizes |

Installation method | Assemble with screws |

Applicable vehicle models | Off-road vehicles (such as: Wrangler, Jimny, Land Cruiser, etc.), pickup trucks (such as: Hilux,, etc.), urban SUVs (such as: Forester, RAV4, etc.), commercial vehicles (such as: Mercedes-Benz V260 Toyota Hiace, etc.), and 99% of the models on the market are applicable. |

Product Highlights | 1. The four-week symmetrical appearance design is adopted, and the overall layout is more coordinated and beautiful. 2. The thickest of the material in the main frame is 2.6mm, which is more solid and less likely to deform. 3. The combination of longitudinal aluminum plates and transverse aluminum bars is used and the overall load-bearing capacity will be stronger. 4. The surface is treated with deep electrophoretic coating and high-quality powder spraying, which makes the's rust and anti-corrosion performance more excellent. |

Reliable Contract Manufacturer

With years of professional experience and advanced production equipment, we create high-performance and highly durable accessories to meet the needs of global dealers.

the delivery period is short

Since we are the same team from design to production, our delivery period is relatively short, which is ahead of the same industry.

Strict production and quality inspection standards

We have strict production process control and a professional quality control team, and a secondary check will also be conducted before shipment.